Maximize Energy Efficiency and Reduce Costs with Comprehensive Monitoring

In the beer production process, fermentation is one of the most critical stages. Monitoring it accurately ensures that the beer develops the desired flavors, alcohol content, and quality. The Fermentation Monitor QWX43 is a cutting-edge device designed to provide continuous and precise monitoring of all essential fermentation parameters, transforming the way breweries manage this crucial phase of production.

Fermentation Monitor QWX43

The Fermentation Monitor QWX43 is installed directly in the fermentation tank and measures directly Density, Viscosity, Acoustic Velocity and Temperature.

The monitor calculates all relevant fermentation parameters, such as degree of fermentation, residual extract, and alcohol content, the sugars of the wort or the fermentation rate.

How the QWX43 works

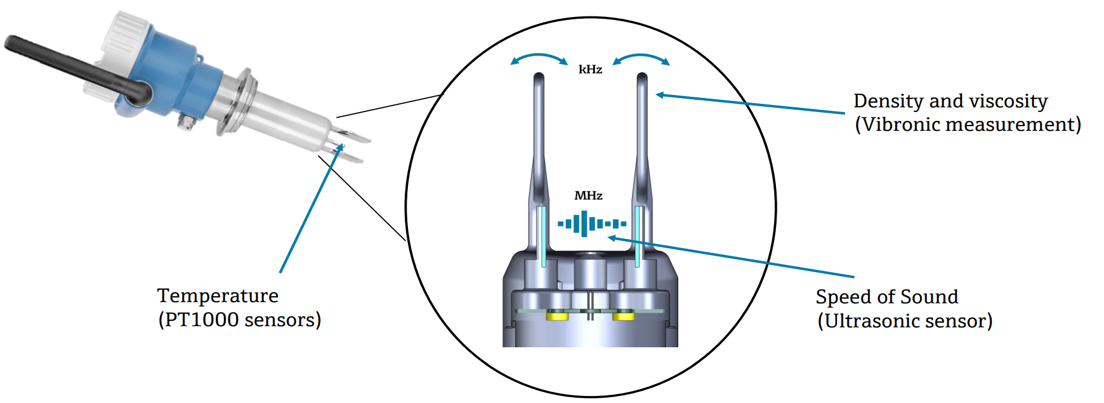

The measurement method is based on a combination of the vibronic principle with an integrated temperature measurement and a sound velocity measurement using ultrasound

- Pt1000 for greater accuracy, and Compensation

- The 2 Vibronic Forks for Density and Viscosity Calculations via the measurement of the frequency changes when in contact with the product

- The Speed of sound to get the Acoustic Velocity to obtain factors like alcohol percentages or CO2 gas bubbles

- The sensors measure density to assess fermentation and viscosity to control and predict quality and predict filtering times

Key Features of the QWX43:

- Real-time monitoring: Continuous, minute-by-minute data replaces manual sampling and lab analysis.

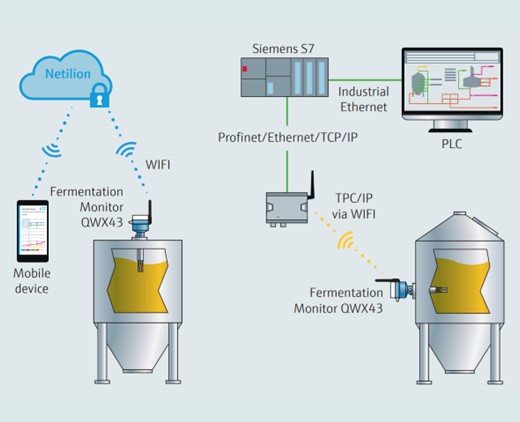

- Remote access: Data can be viewed from any internet-enabled device via the Endress+Hauser Netilion app, ensuring constant oversight.

- Automation: The QWX43 automatically logs and analyzes batch data, reducing manual tracking and documentation.

- Process optimization: The data-driven system helps optimize brewing by comparing past batches and sending automatic alerts for deviations.

The Advantage for Breweries:

- Precise and Repeatable Measurements: Real-time data ensures more accurate control over fermentation, leading to consistently high-quality beer.

- Efficient Process Control: Brewers can retrieve fermentation information instantly, enabling faster response times to potential issues.

- Cost and Time Savings: The automation and data logging functions significantly reduce labor and the time spent on process supervision, freeing up resources for other areas of production.

- Improved Documentation: All data is automatically recorded and stored, providing detailed records that can be used for quality control, audits, and improving future batches.

Benefits

Automated Fermentation Control

Reduces manual sampling and lab analysis, freeing up staff and increasing efficiency.

Optimized Quality Control

Ensures consistent product quality by providing real-time data on critical parameters

Cost Efficiency

Low maintenance requirements and quick installation minimize operating costs.

Hygienic Design

The closed-loop system with a cleanable sensor minimizes contamination risks, ideal for maintaining product integrity.

Energy and Process Optimization

Enables quick responses to process changes, reducing energy use and product waste, and ensuring consistent quality for low/no-alcohol beers.

Predictive Capabilities

Provides alerts on potential issues and estimates fermentation completion time, improving process reliability and scheduling.

- With over 20 years of experience in electrical engineering and automation we customize and deploy our solutions to suit any type of building in any industry and at any scale.

- We deploy our solution in conformance to international standards and protocols ensuring interoperability with systems and solutions from the world’s best brands in automation and integrated systems

- We offer upgrades for obsolete systems and collaborate with you to scale up existing systems to save cost and meet your business objectives.

- Leverage on our experience and access to Original Equipment Manufacturers to implement the latest technologies in electrical, instrumentation and controls engineering.

TAGG is your number one partner for smart solutions. We deploy custom packages based on your immediate requirements.

Our deployments are designed with future expansion in mind and can be scaled up as your needs expand.

We offer after sales support services including:

- warranty,

- maintenance,

- troubleshooting and

- supply of spares.

- General Electrical Installation Services

- Upgrade of obsolete systems to modern solutions

- Systems Audit (Energy, Power Quality)

- Maintenance services

- Troubleshooting Services

- Training

- Spares

Explore Other Solutions

Distribution Boards: 5 Advanced Distribution Solutions

Distribute power efficiently and safely with ESL’s Power Distribution Panels. These customizable panels offer advanced protection and monitoring features, making them ideal for a wide range of applications, from residential buildings to large industrial plants.

Learn More

Optimizing Aeration in Wastewater Treatment

Efficient aeration is crucial in wastewater treatment plants, where energy consumption can skyrocket. Our solution streamlines the aeration process, drastically reducing energy usage while maintaining

Learn More

Inventory Monitoring and Tank Gauging

Optimize inventory levels and enhance storage utilization with advanced monitoring solutions. Endress+Hauser provides comprehensive turnkey systems that include smart radar level sensors, gateways, and cloud-based software for real-time data visualization and ERP integration.

Learn More

Uninterruptible Power Supply

We can help prevent losing critical data or experiencing costly downtime due to a sudden power surge or blackout. Let’s help you safeguard your operations from costly power outages, protecting your equipment, preventing data loss, and ensuring seamless production flow.

Learn More

Automated Inventory Management

We leverage our automation expertise to create integrated inventory management solutions. By linking your PLC systems with inventory tracking software, you gain real-time visibility into stock levels, triggering automatic reorders when necessary. This minimizes stockouts, optimizes storage space, and reduces waste.

Learn More

PLC & SCADA Programming

Complete control over your production process. Our skilled engineers create custom PLC programs to automate tasks, monitor performance in real-time. Every step, from mixing ingredients to final packaging is meticulously controlled and monitored ensuring consistent quality in every batch, eliminating the risk of human error and wasted ingredients.

Learn More