Optimizing Aeration in Wastewater Treatment

In the food and beverage industry, wastewater treatment is a critical component. Our advanced aeration monitoring and control system is designed to significantly reduce energy consumption while maintaining optimal water quality. Given that aeration accounts for 45-75% of total energy use in wastewater treatment, optimizing this process is crucial for both operational efficiency and environmental compliance.

Hardware/Software

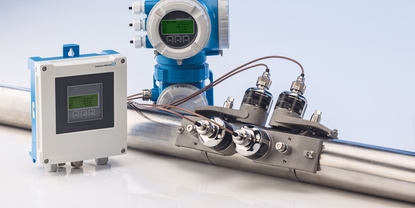

- Dissolved Oxygen Sensor (Oxymax COS61D)

- Pressure Transmitter (Deltabar PMP51B)

- Liquiline transmitter for data recording and pump control ( CM44x)

- Active Power measurement with an Energy Meter

Benefits

Energy Savings

Reduce energy consumption by up to 70% with optimized aeration, drastically lowering operational costs.

Enhanced Treatment Efficiency

Maintain optimal dissolved oxygen levels for efficient bacterial activity, ensuring high water quality.

Regulatory Compliance

Meet environmental regulations by optimizing the nitrification process and reducing harmful ammonia levels.

Reduced Maintenance Costs

Continuous monitoring decreases the likelihood of equipment failures, minimizing downtime and maintenance expenses.

- With over 20 years of experience in electrical engineering and automation we customize and deploy our solutions to suit any type of building in any industry and at any scale.

- We deploy our solution in conformance to international standards and protocols ensuring interoperability with systems and solutions from the world’s best brands in automation and integrated systems

- We offer upgrades for obsolete systems and collaborate with you to scale up existing systems to save cost and meet your business objectives.

- Leverage on our experience and access to Original Equipment Manufacturers to implement the latest technologies in electrical, instrumentation and controls engineering.

TAGG is your number one partner for smart solutions. We deploy custom packages based on your immediate requirements.

Our deployments are designed with future expansion in mind and can be scaled up as your needs expand.

We offer after sales support services including:

- warranty,

- maintenance,

- troubleshooting and

- supply of spares.

- General Electrical Installation Services

- Upgrade of obsolete systems to modern solutions

- Systems Audit (Energy, Power Quality)

- Maintenance services

- Troubleshooting Services

- Training

- Spares

Explore Other Solutions

Distribution Boards: 5 Advanced Distribution Solutions

Distribute power efficiently and safely with ESL’s Power Distribution Panels. These customizable panels offer advanced protection and monitoring features, making them ideal for a wide range of applications, from residential buildings to large industrial plants.

Learn More

Monitoring the Fermentation Process in Beer Production

Implement the QWX43 Fermentation Monitor to gain real-time, multi-parameter insights into the fermentation process. This device measures key parameters such as density, temperature, acoustic velocity, and viscosity directly inside the fermentation tank, providing crucial data for optimizing beer quality and consistency.

Learn More

Inventory Monitoring and Tank Gauging

Optimize inventory levels and enhance storage utilization with advanced monitoring solutions. Endress+Hauser provides comprehensive turnkey systems that include smart radar level sensors, gateways, and cloud-based software for real-time data visualization and ERP integration.

Learn More

Uninterruptible Power Supply

We can help prevent losing critical data or experiencing costly downtime due to a sudden power surge or blackout. Let’s help you safeguard your operations from costly power outages, protecting your equipment, preventing data loss, and ensuring seamless production flow.

Learn More

Automated Inventory Management

We leverage our automation expertise to create integrated inventory management solutions. By linking your PLC systems with inventory tracking software, you gain real-time visibility into stock levels, triggering automatic reorders when necessary. This minimizes stockouts, optimizes storage space, and reduces waste.

Learn More

PLC & SCADA Programming

Complete control over your production process. Our skilled engineers create custom PLC programs to automate tasks, monitor performance in real-time. Every step, from mixing ingredients to final packaging is meticulously controlled and monitored ensuring consistent quality in every batch, eliminating the risk of human error and wasted ingredients.

Learn More